Custom Box Dividers

Box dividers, also known as box partitions, are primarily used to create compartments in your packaging to separate and store multiple products in one box. Box partitions can be corrugated for extra protection of fragile products during transit, or made with lightweight paperboard for smaller items. Box dividers can be fully customized and are perfect for organizing your products inside your packaging. Whether you're looking to separate lightweight products such as cookies or fragile items such as glass bottles, we've got just the solution.

Partitions for BoxesFully customizable

All box dividers can be fully customized by size and number of compartments. Get them fully printed with your brand for a beautiful unboxing experience. Sturdy and durable

Custom packaging dividers are perfect for organizing different sized products in a single box, and prevent products from bumping into each other in transit. MOQ from 300 units

Minimums starting from 300 units per size or design when ordered with the outer box. Standalone dividers start with an MOQ of 500 units. |

Available in 2 Standard Styles

The style of divider to use would depend on the size and number of compartments you're looking for. Not to worry - our team will help determine which divider style is best for your use case!

The style of divider to use would depend on the size and number of compartments you're looking for. Not to worry - our team will help determine which divider style is best for your use case!

|

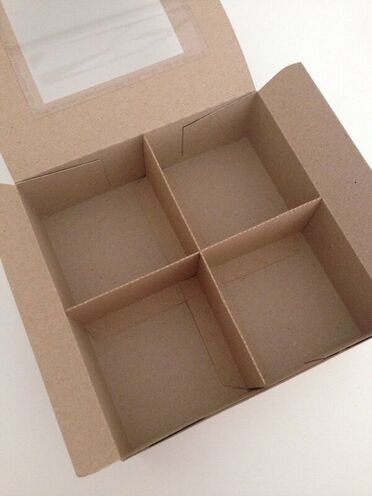

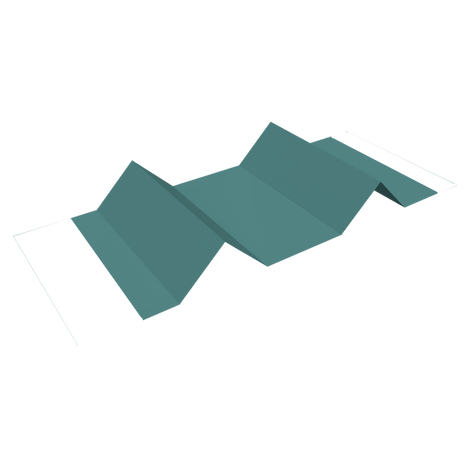

One Piece Box Dividers

These dividers come as 1 piece of paper or corrugated material that's folded up to create compartments. These types of dividers are best for single row compartments or compartments that have varying sizes. |

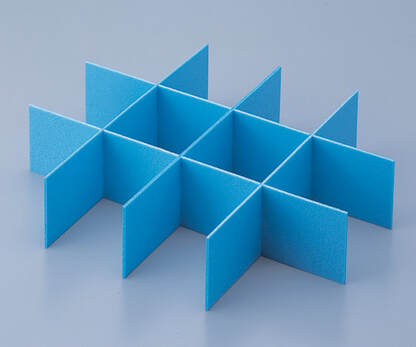

Multiple Piece Partitions

These partitions are made up of separate pieces of paper or cardboard that's connected together to form compartments. Multiple piece partitions are best for creating equal sized compartments spanning multiple rows |

Technical Specs: Custom Box Dividers

An overview of the standard customizations available for custom box dividers and partitions.

An overview of the standard customizations available for custom box dividers and partitions.

Corrugated Materials

|

Box dividers that are corrugated (the wavy lines in cardboard) are stronger and ensure the divider walls are sturdy. Corrugated dividers are typically used for heavier items, fragile items, or items that will be shipped and need extra cushioning/protection

|

E-flute

Most commonly used option and has a flute thickness of 1.2-2mm |

B-flute

Ideal for large boxes and heavy items, with a flute thickness of 2.5-3mm |

|

Designs are printed on these base materials which is then glued to the corrugated board. All materials contain at least 50% post-consumer content (recycled waste).

|

White

Clay Coated News Back (CCNB) paper that's most ideal for printed corrugated solutions WhiteClay Coated News Back (CCNB) paper that's most ideal for printed corrugated solutions |

Brown Kraft

Unbleached brown paper that is ideal for only black or white print. |

Non-corrugated Materials

|

Box dividers that are non-corrugated are typically used for lightweight items, separating items that will just be on display (not shipped), or for organizing products in small boxes

Non-corrugated dividers use a standard paper thickness of 300-400gsm. These materials contain at least 50% post-consumer content (recycled waste). |

White

Solid Bleached Sulfate (SBS) paper that yields high quality print. |

Brown Kraft

Unbleached brown paper that is ideal for only black or white print. |

|

All packaging is printed with soy-based ink, which is eco-friendly and produces much brighter and vibrant colors

|

CMYK

CMYK is the most popular and cost effective color system used in print |

Pantone

For accurate brand colors to be printed and is more expensive than CMYK. |

Coating

|

Coating is added to your printed designs to protect it from scratches and scuffs

|

Varnish

An eco-friendly water-based coating but doesn't protect as well as lamination |

Lamination

A plastic coated layer that protects your designs from cracks and tears, but not eco-friendly. |

Finishes

|

Top off your packaging with a finish option that completes your package.

|

Matte

Smooth and non-reflective, overall softer look. Satin Semi-shiny, in between a matte and glossy look. |

Glossy

Shiny and reflective, more prone to fingerprints. Soft touch Looks like a matte finish, but feels like velvet. |

Related Products and Services: